The poultry industry is undergoing a digital revolution. Smart poultry farming is no longer a futuristic concept – it’s happening right now on farms around the world. At the heart of this transformation? Data. And one of the most valuable data sources is automated weighing.

What Is Smart Poultry Farming?

Smart poultry farming using IoT means connecting devices, sensors, and systems to collect and analyze data in real time. Temperature sensors, feed dispensers, ventilation controls, and weighing platforms all communicate with each other.

The result? Farmers make better decisions faster. Problems are detected early. Resources are used efficiently. Animal welfare improves.

IoT based smart poultry farming turns a traditional poultry house into an intelligent ecosystem where every parameter is monitored and optimized.

Why Weighing Systems Matter in a Smart Farm

Among all the technologies available, poultry weighing systems stand out for one simple reason: weight is the most important indicator of flock performance.

Bird weight tells you:

- Whether the flock is growing according to targets

- If feed conversion is efficient

- When birds are ready for processing

- Whether there are hidden health issues

Without accurate weight data, you’re flying blind. With it, you have a foundation for every other decision on the farm.

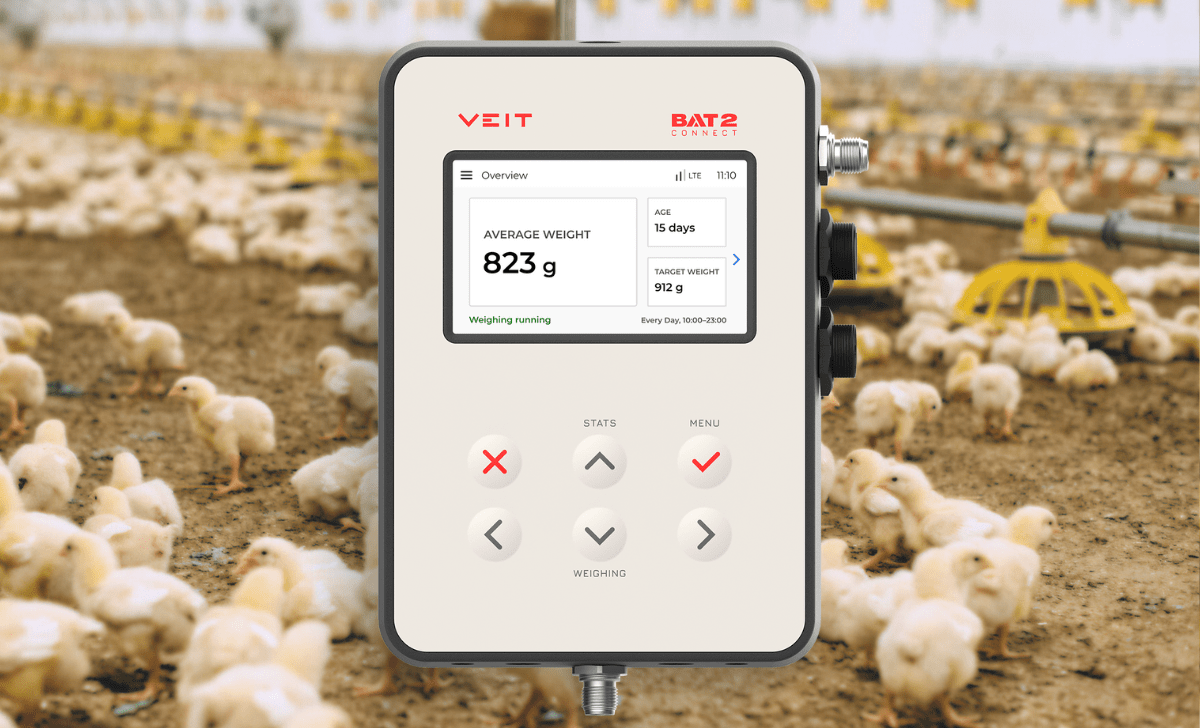

How Automatic Poultry Weighing Systems Work

Traditional weighing means catching birds manually. It’s stressful for the animals and time-consuming for workers. The sample size is small, and accuracy suffers.

Automatic poultry weighing systems solve these problems. Here’s how they work:

- A platform scale is placed inside the poultry house

- Birds step onto it voluntarily throughout the day

- The system records hundreds or thousands of measurements

- Software calculates average weight, weight distribution, and daily gain

- Data is sent to a central dashboard or cloud platform

No catching. No stress. No guesswork. Just continuous, reliable data.

Integration With Smart Farm Technology

The real power of smart farm technology comes from integration. Modern weighing systems don’t work in isolation – they connect with other farm systems.

Feed management – Weight data helps calibrate feed amounts. If birds are underweight, the system adjusts. If they’re gaining too fast, it scales back.

Climate control – Bird weight correlates with environmental conditions. Integrated systems can adjust temperature and ventilation based on growth patterns.

Health monitoring – A sudden drop in weight gain often signals disease. Connected systems can trigger alerts before the problem spreads.

Processing planning – Accurate weight predictions help schedule slaughter at optimal times, maximizing yield and quality.

This is poultry precision farming in action – every input optimized, every output measured.

The Role of Digital Livestock Management

Digital livestock management platforms bring all this data together in one place. Farmers can monitor multiple houses or even multiple farms from a single interface.

Key features include:

- Real-time dashboards with weight trends and alerts

- Historical data for comparing flock performance across cycles

- Automated reports for compliance and record-keeping

- Remote access via smartphone or computer

For large-scale operations, this level of visibility is essential. For smaller farms, it levels the playing field.

Poultry Farm Automation: Beyond Weighing

Weighing is just one piece of poultry farm automation. Other automated systems include:

- Feeding systems that dispense precise amounts at scheduled times

- Egg collection systems in layer operations

- Lighting programs that simulate natural day cycles

- Waste removal and cleaning systems

When these systems share data, the entire farm becomes more efficient. A smart poultry farm automation and monitoring system coordinates all of them, reducing labor and improving outcomes.

Tip: Start with weighing if you’re new to automation. It’s relatively affordable, easy to install, and delivers immediate ROI through better feed efficiency and timing.

Is Smart Farming Worth the Investment?

The short answer: yes.

Farms using IoT based smart poultry farming report:

- Lower feed costs through optimized conversion ratios

- Reduced mortality from early problem detection

- Higher yields from precise processing timing

- Less labor through automation

- Better traceability for quality assurance

The initial investment pays back quickly – often within the first year.

Getting Started

You don’t need to automate everything at once. Many farmers start with a single automatic poultry weighing system and expand from there.

Look for systems that offer:

- High accuracy and durability

- Cloud connectivity for remote monitoring

- Easy integration with other farm technologies

- Reliable support and service

Smart poultry farming isn’t about replacing farmers. It’s about giving them better tools to do what they’ve always done – raise healthy birds efficiently.

Conclusion

Poultry weighing systems are a cornerstone of modern digital livestock management. They provide the data that drives smarter decisions across the entire operation.

As smart farm technology continues to evolve, farms that embrace automation will have a significant advantage. The future of poultry farming is connected, data-driven, and precise.

And it starts with knowing exactly how much your birds weigh.

YOU MAY ALSO LIKE: Unlocking Efficiency: The Rise of Automated Pre-Roll Production